- +86 187 3271 1873/+86 132 8322 1383

- ssinvestment@cenchogroup.com

3-piece ball valve is preferred wherever regular cleaning is required.

They are widely used for a variety of sanitary applications that are required for pharmaceutical and food/beverage industries.

A unique advantage of the 3 piece valve design is that the ball valve ends can remain threaded into the pipe, while the center section containing the ball can be removed

Products Description

Features:

Precision casting three-piece ball valve (high platform)

Pressure rating: 1000PSI (PN63)

Thread standard: ANSI B 2.1, BS21, ISO7/1

Drive disk standard: ISO5211

Working temperature: -25℃+180℃

Material: CF8M, CF8, CF3M, WCB

Advantages and Usage:

3 piece stainless Steel ball valves also called 3 SS ball valves. The valve body is composed of 3 separate pieces held together by bolts, which can be easily removed for cleaning and servicing. A 3-piece ball valve is preferred wherever regular cleaning is required. A unique advantage of the 3 piece valve design is that the ball valve ends can remain threaded into the pipe, while the center section containing the ball can be removed. They are widely used for a variety of sanitary applications that are required for pharmaceutical and food/beverage industries. These 3 piece ball valves have been specifically designed to be easily disassembled, cleaned, and reassembled

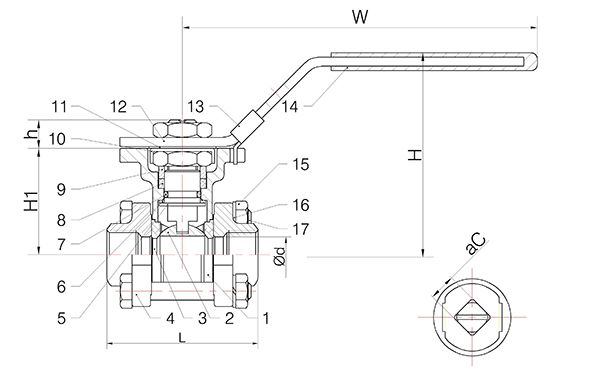

Material List

ITEM | PART | MATERIAL | QTY | |||

1 | BODY | A216-WCB | A351-CF8 | A351-CF8M | 1 | |

2 | BALL | 304 | 304 | 316 | 1 | |

3 | SEAT | PTFE/RPTFE | 2 | |||

4 | CAP | A216-WCB | A351-CF8 | A351-CF8M | 1 | |

5 | STEM | 304 | 304 | 304 | 2 | |

6 | THRUST WASHER | PTFE | 1 | |||

7 | O-RING | VITON | 1 | |||

8 | PACKING | PTFE | 1 | |||

9 | GLAND NUT | 304 | 1 | |||

10 | STOPPER NUT | 304 | 1 | |||

11 | PLATE | 304 | 1 | |||

12 | HANDLE | 304 | 1 | |||

13 | LOCK | 304 | 1 | |||

14 | HANDLE COVER | PLASTIC | 2 | |||

15 | NUT | 304 | 304 | 304 | 4(6) | |

16 | SPRING WASHER | 304 | 4(6) | |||

17 | BOLT | 304 | 304 | 304 | 4(6) | |

18 | STOP PIN | 304 | 304 | 304 | 1 | |

Dimension Table

SIZE | Φd | L | H | W | H1 | h/aC | ΦD | ISO5211 | N.M | KGS | |

DN6 | 1/4’’ | 12.5 | 52 | 60 | 140 | 30 | 9 | 18 | F03 | 4 | 0.41 |

DN10 | 3/8’’ | 12.5 | 52 | 60 | 140 | 30 | 9 | 18 | F03 | 4 | 0.43 |

DN15 | 1/2’’ | 15 | 62 | 68 | 140 | 36.5 | 9 | 18 | F03/F04 | 5 | 0.55 |

DN20 | 3/4’’ | 20 | 72 | 72 | 140 | 40.5 | 9 | 27.2 | F03/F04 | 8 | 0.70 |

DN25 | 1’’ | 25 | 79 | 86 | 160 | 48.5 | 11 | 31 | F04/F05 | 10 | 0.98 |

DN32 | 1-1/4’’ | 32 | 94 | 94 | 160 | 53 | 11 | 42.8 | F04/F05 | 14 | 1.56 |

DN40 | 1-1/2’’ | 38 | 103 | 101 | 185 | 61.5 | 14 | 48.6 | F05/F07 | 18 | 2.19 |

DN50 | 2’’ | 50 | 126 | 110 | 185 | 70.5 | 14 | 60.5 | F05/F07 | 25 | 3.18 |

DN65 | 2-1/2’’ | 65 | 158 | 143 | 230 | 95.5 | 17 | 76.3 | F07/F10 | 48 | 6.23 |

DN80 | 3’’ | 76 | 179 | 157 | 230 | 109 | 17 | 90 | F07/F10 | 75 | 8.31 |

DN100 | 4’’ | 94 | 213 | 182 | 320 | 131 | 22 | 116 | F07/F10 | 110 | 14.36 |