- +86 187 3271 1873/+86 132 8322 1383

- [email protected]

The three-way valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metals and radioactive media.

Products Description

The three-way valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metals and radioactive media. According to the material, the three-way valve is also divided into cast iron valve, cast steel valve, stainless steel valve, chromium molybdenum steel valve, chromium molybdenum vanadium steel valve, duplex steel valve, plastic valve, non-standard customized valve materials.

Investment castings for body and cap

Internal entry blow-out proof stem

Pressure Rating:1000PSI(PN63)

Thread End:ANSI B2.1, BS21,ISO7/1

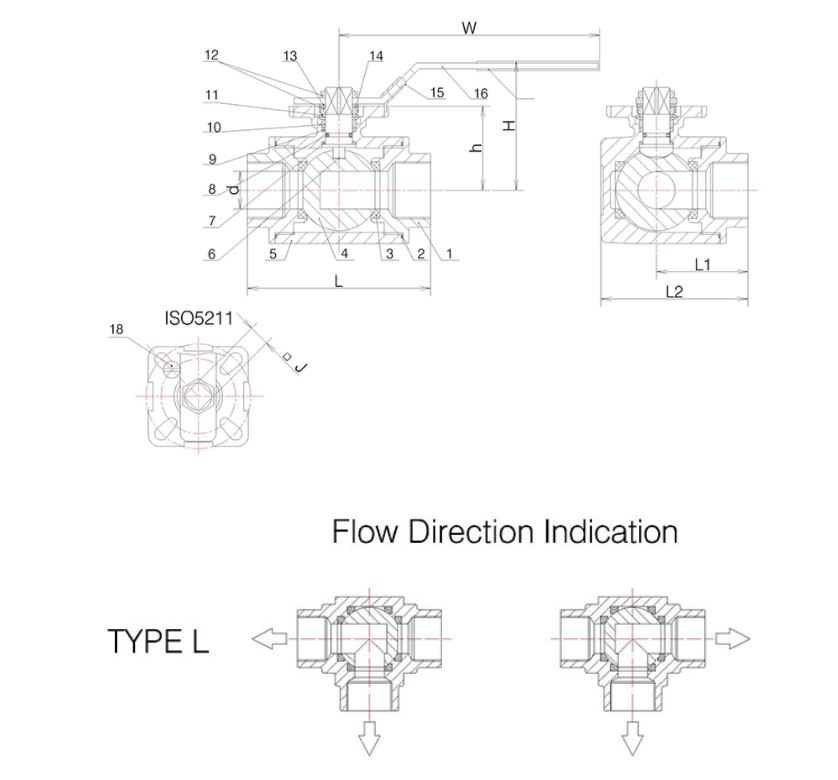

Mounting Pad: ISO5211 Working Temperature:-25℃~+180℃

Material:CF8M,CF8,CF3M,WCB

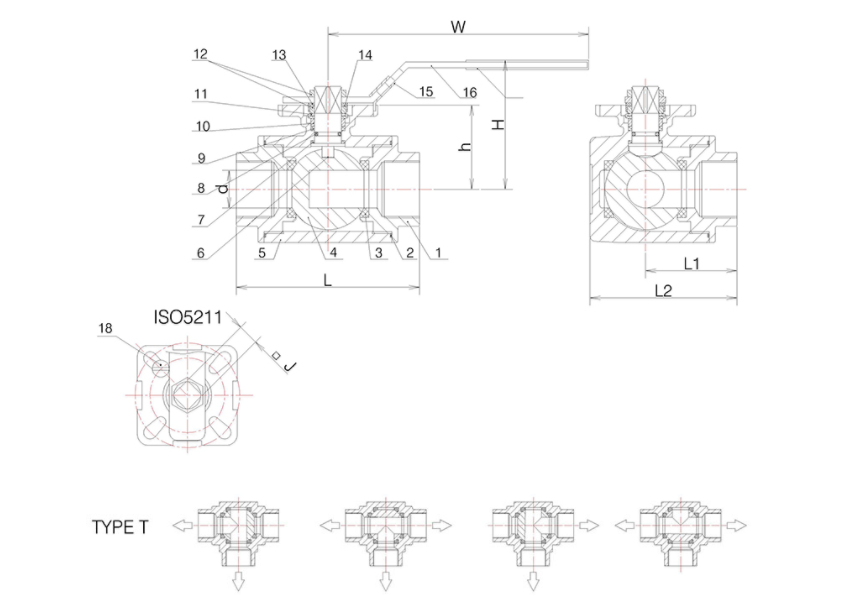

Material List

ITEM | PART | MATERIAL | QTY | ||

2 | CAP | A216-WCB | A351-CF8 | A351-CF8M | 3 |

GASKET | PTFE | 3 | |||

3 | SEAT | PTFE/RPTFE | 4 | ||

4 | BALL | 316 | 1 | ||

5 | BODY | A216-WCB | A351-CF8 | A351-CF8M | 1 |

6 | STEM | 304 | 304 | 316 | 1 |

7 | STEM THRUST WASHER | PTFE | 1 | ||

8 | O RING | VITON | 1 | ||

9 | PACKING | 304 | 1 | ||

10 | GLAND NUT | 304 | 304 | 304 | 1 |

11 | BELLWVLLE WASHER | 301 | 1 | ||

12 | NUT | 304 | 2 | ||

13 | PLATE WASHER | 304 | 1 | ||

14 | STOPPER NUT | 304 | 1 | ||

15 | LOCK | 304 | 1 | ||

16 | HANDLE | 304 | 1 | ||

17 | HANDLE COVER | PLASTIC | 1 | ||

18 | STOP PIN | 304 | 1 | ||

DIMENSION TABLE

SIZE | Φd | L | H | W | h | L1 | J | ISO5211 | L2 | N.M | KGS | |

DN6 | 1/4’’ | 9.5 | 75 | 66 | 130 | 36.8 | 37.5 | 9 | F03/F04 | 57.5 | 8 | 0.71 |

DN10 | 3/8’’ | 11 | 75 | 66 | 130 | 36.8 | 37.5 | 9 | F03/F04 | 57.5 | 8 | 0.68 |

DN15 | 1/2’’ | 12 | 75 | 66 | 130 | 36.8 | 37.5 | 9 | F03/F04 | 57.5 | 8 | 0.64 |

DN20 | 3/4’’ | 15 | 85 | 72 | 161 | 41.2 | 42.5 | 11 | F04/F05 | 65.5 | 9 | 0.95 |

DN25 | 1’’ | 20 | 100 | 77 | 161 | 46.5 | 50 | 11 | F04/F05 | 79 | 15 | 1.40 |

DN32 | 1-1/4’’ | 25 | 122 | 92 | 203 | 56 | 61 | 14 | F05/F07 | 97 | 20 | 2.90 |

DN40 | 1-1/2’’ | 32 | 131 | 96 | 203 | 60 | 65.5 | 14 | F05/F07 | 106.5 | 30 | 3.65 |

DN50 | 2’’ | 40 | 158 | 107 | 203 | 70.5 | 79 | 14 | F05/F07 | 129 | 45 | 6.30 |

DN65 | 2-1/2’’ | 49 | 178 | 135 | 254 | 95.5 | 89 | 17 | F07/F10 | 145 | 60 | 8.96 |

DN80 | 3’’ | 60 | 202 | 147 | 254 | 106 | 101 | 17 | F07/F10 | 167 | 90 | 13.10 |

DN100 | 4’’ | 75 | 246 | 160 | 310 | 119 | 123 | 17 | F07/F10 | 203 | 120 | 22.11 |