- +86 187 3271 1873/+86 132 8322 1383

- [email protected]

In a bustling city in the United States, a local paving contractor had outgrown their existing equipment. Known for their quality work and attention to detail, the company was facing a growing demand for small, complex paving projects in residential neighborhoods and commercial plazas. Their traditional paving equipment was too large and cumbersome for these jobs, resulting in inefficiencies and unhappy customers.

Customers needed a solution that would allow them to efficiently complete small-scale paving projects without compromising on quality. Their existing machinery was not only too large but also difficult to maneuver in tight spaces. This resulted in increased labor costs and longer project timelines, which in turn affected their profitability and customer satisfaction.

After extensive research, Customers decided to invest in the Mini 360 paver. Known for its compact size, agility, and precision, the Mini 360 paver promised to be the perfect solution for their needs. The company was particularly impressed by its ability to pave narrow pathways, driveways, and small parking lots with ease.

The custom Mini 360 paver was quickly integrated into the Customer's fleet. The team received comprehensive training on how to operate the new machine, ensuring they could maximize its potential from day one. The compact design and advanced maneuverability of the Mini 360 paver allowed the team to tackle projects that were previously considered too challenging with their old equipment.

● Increased Efficiency: The Mini 360 paver significantly reduced the time required to complete small-scale paving projects. What used to take days could now be finished in a matter of hours.

● Cost Savings: The efficiency gains translate into lower labor costs and reduced fuel consumption. This allowed the customer to take on more projects without increasing their operational expenses.

● Enhanced Quality: The precision of the Mini 360 paver ensured that the finished surfaces were smooth and even, leading to higher customer satisfaction. The company received numerous compliments from clients who were impressed with the quality and speed of their work.

● New Opportunities: With the ability to handle smaller projects more effectively, customers expanded their service offerings. They began taking on more residential projects and secured several contracts for commercial plazas and parks, which were previously out of reach.

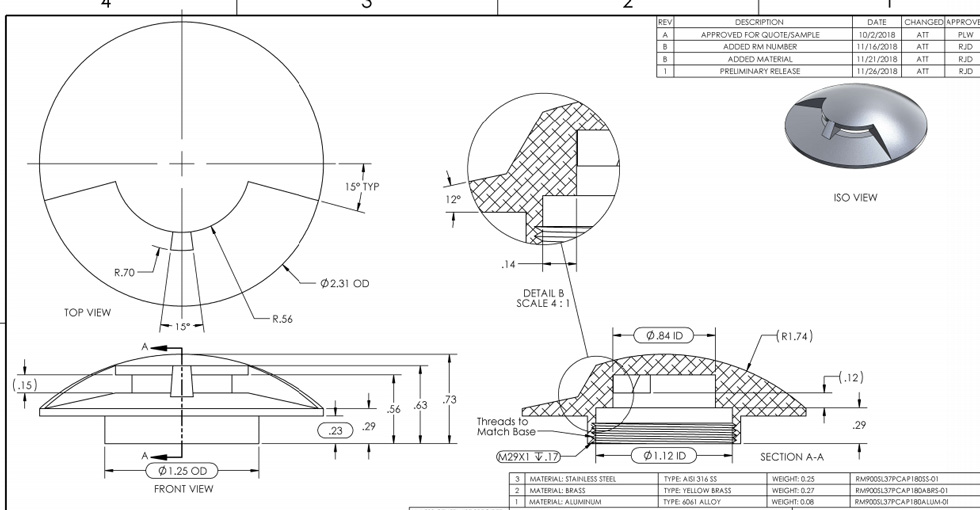

Production batch: 100-250- 500+ pieces. Please provide a quotation for all the parts you can produce.

Please provide mold quotation, including investment casting and die casting for mold and production respectively

The customer shared his thoughts on the Mini 360 paver: "The Mini 360 paver has been a game-changer for our business. Its compact size and precision have allowed us to complete projects we used to struggle with. Our clients are happier, and we're able to take on more work than ever before. It's been a fantastic investment."

The introduction of the Mini 360 paver transformed customer's operations, enabling them to deliver high-quality paving services more efficiently and effectively. This investment not only improved their bottom line but also strengthened their reputation as a reliable and innovative paving contractor in Denver. The success story of the customer demonstrates the powerful impact that the right equipment can have on a business's growth and customer satisfaction.

Welcome to our custom precision castings, we customize a variety of accessories to meet your application requirements.